Overview

Manufacturing industry is always faced with challenges to maximize equipment productivity, improve yield, minimize equipment operational losses, reduce scrap.

Sapphire Automation products and solution in equipment automation/control space provides tools to address all these problems very efficiently. Developed by industry veterans this GUI driven interactive system easily integrates to other manufacturing systems actively monitors and logs data in real-time, while automatically generating required reports. This highly automated solution enables process owners to easily track equipment performance, receive alerts and alarms.

Products

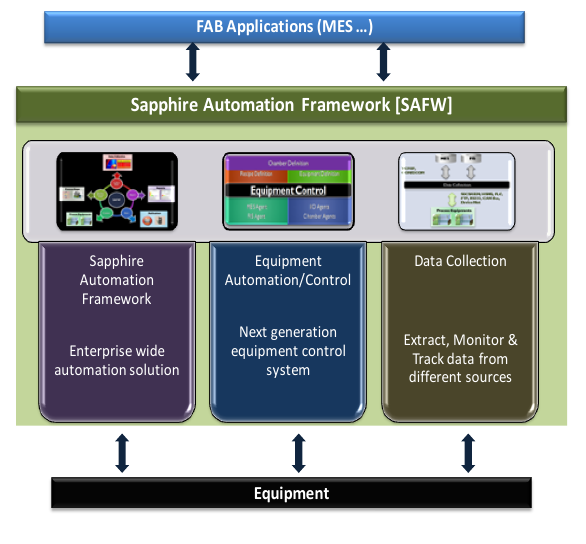

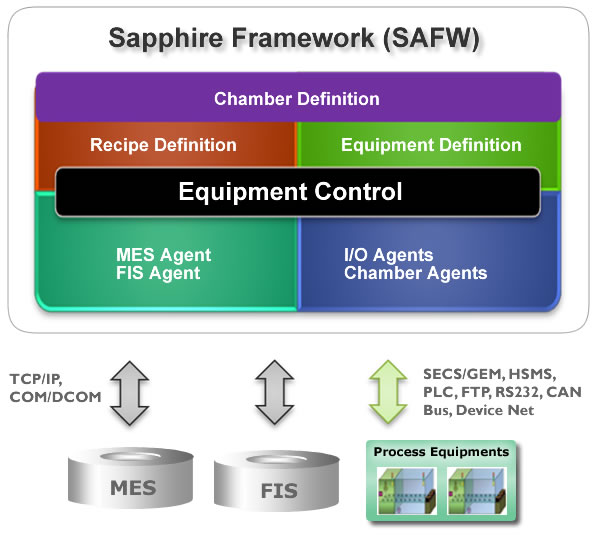

Sapphire Automation Framework [SAFW]

Sapphire Automation is an enterprise wide equipment automation solution which helps customers achieve their goal of complete factory automation within short period of time

SAFW has modular architecture . Each module works independently and with SAFW. Main modules are Data Collection and Equipment Automation/Control

Data Collection

Data Collection is an enterprise wide solution for collecting data real time from various tools. It supports various hardware and protocols collecting data providing traceability for easy debugging.

Equipment Automation

Sapphire Equipment Control accelerates equipment automation compliance to standards by working with individual tool vendor, to conform manufacturers needs.

About Sapphire Automation Inc.

Sapphire Automation provides enterprise wide solution with proactive performance problem identification and remediation prior to business impact; including data logging at nano secs level, Root Cause Analysis. For more information please visit our website at www.gosapphire.com or email us at marketing@gosapphire.com

Sapphire Automation

Framework [SAFW]

Sapphire Automation

How it works

The SAFW’s provides an easy-to-use and highly customizable development environment to take the processing equipment from R&D to Production stage in an accelerated manner. SAFW enables the users with following steps:

- Equipment Hardware Definition

- Equipment Configuration Definition

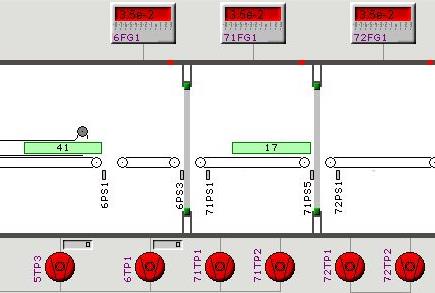

- Convert Schematic into Equipment Maintenance Screen

- Deploy and Monitor

Key Features

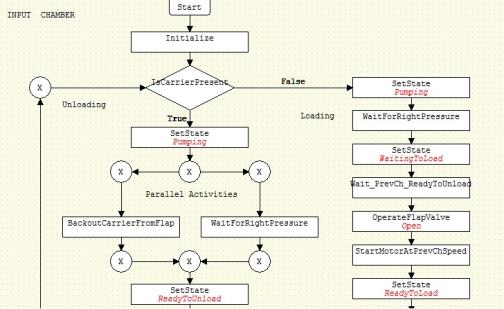

Equipment Operation Definition

Typically, the Equipment operation is written on a paper. The SAFW enables users to mimic and abstract the operation in a flowcharts. This greatly accelerates development understanding of the equipment design and operations such as signals, inter-locking, parallel operation and data generated.

Convert Schematic into Equipment

Maintenance

The SAFW’s open and modular architecture then enables users to generate agents required to connect the GUI to the equipment as well other manufacturing applications.

Equipment Operation Definition

Typically, the Equipment operation is written on a paper. The SAFW enables users to mimic and abstract the operation in a flowcharts. This greatly accelerates development understanding of the equipment design and operations such as signals, inter-locking, parallel operation and data generated.

About Sapphire Automation Inc.

Sapphire Automation provides enterprise wide solution with proactive performance problem identification and remediation prior to business impact; including data logging at nano secs level, Root Cause Analysis. For more information please visit our website at www.gosapphire.com or email us at marketing@gosapphire.com

Equipment Automation

Sapphire Automation

How it works

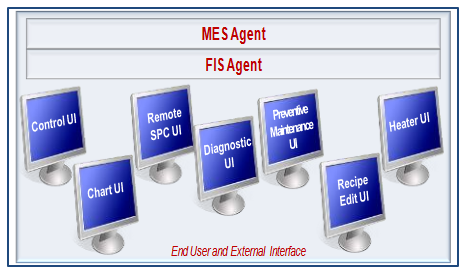

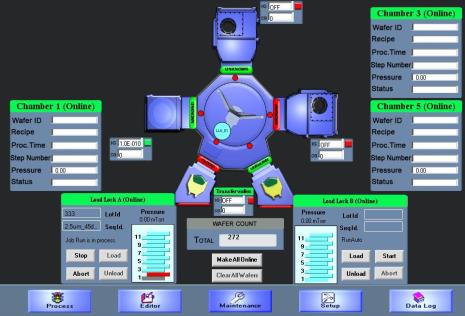

Equipment Automation enables common services, such as, alarm, error handling, data and event logging. In addition it provides objects for connectivity, diagnosis and debugging of various I/O devices, PLCs, Ethernet IO, device net and more… Sapphire’s Equipment automation is Semi Standard compliant. It supports single chamber, cluster tools and inline tools.

Key Features

- User-interface Development

- Flow chart based execution

- GUI Configurable

- Supports Multiple GUI

- Job Management

- Process Control Management

- Real-time process control and monitoring

- Recipe Management

- Alarm Management and Configurable

- Material Handling

About Sapphire Automation Inc.

Sapphire Automation provides enterprise wide solution with proactive performance problem identification and remediation prior to business impact; including data logging at nano secs level, Root Cause Analysis. For more information please visit our website at www.gosapphire.com or email us at marketing@gosapphire.com

Data Collection

Sapphire Automation

How it works

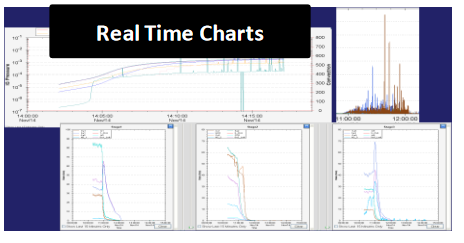

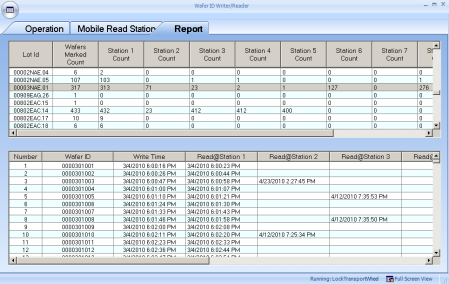

Data Collection provides automated data collection from equipment. Data collection feeds directly into database without affecting active production with no change to the tool software. This process does not affect operation of the tool.

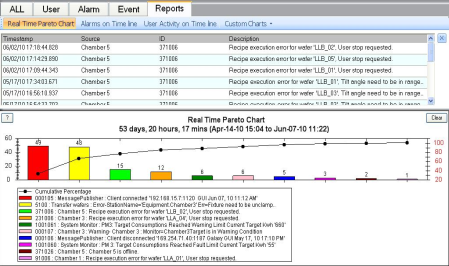

Key Features

Lot – Wafer – Recipe – Parameters History

Complete history based on lot, wafer, recipes and parameters used for DOE, R&D, Pilot and Production. Flow of Lot from the start to the end point can be monitored from one screen only.

Traceability & visibility into every process step with Data Logger

Timely identification the root cause of equipment issues, that lead to equipment downtime and adversely impact business revenue.

Alerts and alarms

Early problem detection and notification

About Sapphire Automation Inc.

Sapphire Automation provides enterprise wide solution with proactive performance problem identification and remediation prior to business impact; including data logging at nano secs level, Root Cause Analysis. For more information please visit our website at www.gosapphire.com or email us at marketing@gosapphire.com